What are the aspects of testing covered through engine dyno testing

Engine calibration optimization – Through Engine dyno testing, it is possible to check the calibration of the parameters like ignition timing, fuel injection timing, air-fuel ratio, valve timing etc. During the testing, the engineers will fine-tune the parameters so the engine will function optimally and have greater fuel efficiency, drivability and performance levels.

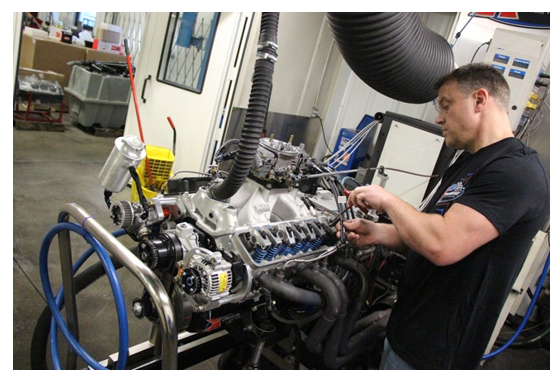

Durability and reliability of the engine – Through dyno testing it is possible to test the engine at various load and capacity levels, making it easier to understand how the engine will perform at various conditions. This would also help the technicians and the manufacturers to understand where the problems lie, if there is a problem, and how to rectify them.

Total performance evaluation – The engineers or technicians assess the performance of the engine under various performance parameters like horsepower, torque, fuel consumption, emissions, etc to see how it works under a range of operating conditions. This would help them evaluate the performance capacity of the engine, and see whether it works according to expectations.

Validate the engine components – The various engine components like camshafts, turbochargers, intake and exhaust systems, and cylinder heads all need to be validated before they are placed within the engine. These enhance the performance and compatibility of the engine, and enable it to work with power output and maximum efficiency.

Comparative analysis testing – It would allow the engineers to try various engine configurations with each other to benchmark the different performance levels. This would help them to understand the performance, strengths and weakness of the components and make informed decisions about what they are capable of. It is also important to test the performance of the engines on different kinds of fuels like biofuels, electricity or hydrogen, and how the engine runs under each of them, and what their performance levels are during that time.

Conclusion

Through effective engine dyno testing, the engineers, technicians and manufacturers will be able to garner essential data regarding the performance of the engines, and how they can develop highly performant, reliable and efficient engines that can be used within a varying range of applications. Ensure top performance of your engines with accurate engine dyno testing, and never face a failure or downtime.